Production scraps are generated on the one hand due to the wear and tear of production equipment and on the other hand due to accidental, mainly human errors. Current control systems typically specialize in detecting the occurrences of the former, regularly occurring errors. With the development of applied information technology and optics, higher levels of control and control methods are also gaining grounds in manufacturing technologies. Complex systems with various sensory controls are currently operating globally, but they have the ability only to examine predefined properties (color, size, component presence) under highly limited conditions; if the product or other environment changes, the whole system needs to be re-tuned, adapted to the specific task, generating time loss and cost.

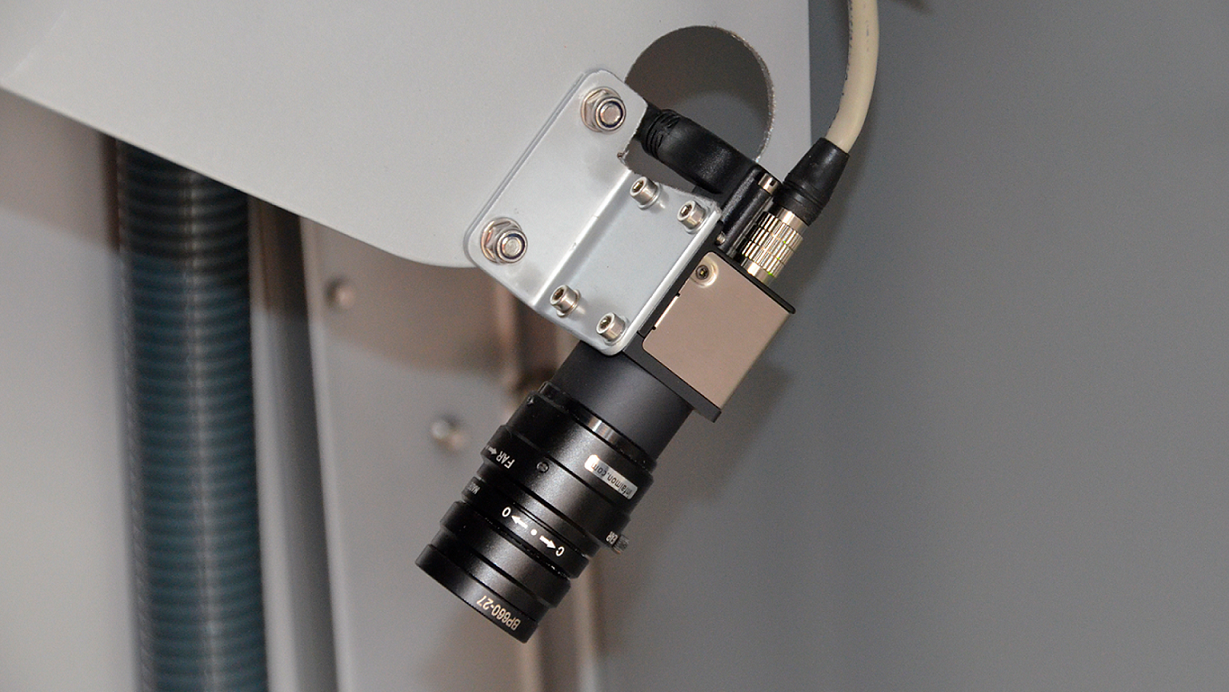

The Algonet PRO system makes these steps unnecessary because, along with the specific problem, in the individual manufacturing environment automatically determines the environment and product: it prepares the model of the product, it does not need to pre-define the item to be tested and makes a model of the environment that can adapt to changes, so it does not require a fixed design, blanketing, shading and illumination; the models are continuously refined, it can continue to function even in case of major changes without operator or maintenance intervention; can handle multiple products simultaneously, produce multiple product models in parallel without separate (custom, special) settings.

Algonet PRO provides more comprehensive, more consistent and balanced results in the full spectrum of error detection than competing solutions, but its main feature is to filter out unique and critical errors that traditional systems can not process.

IF YOUR ENTERPRISE

manufactures any kind of product on production line, wants to effectively reduce the waste number, spends a significant amount of money for quality control, Algonet PRO is an optimal solution for you!

SALES AND FURTHER INFORMATION

The world’s first adaptive and self-learning industrial error detection system

HUNGARIAN INNOVATION, HUNGARIAN DEVELOPMENT

It is suitable for controlling any series of products manufactured on a production line, such as a sour cream cup, furniture element or vehicle component

A sure way to reduce quality control costs

The Algonet PRO a revolutionary innovation-based optical defect control and recognition system; for identifying faults it does not look for specific abnormalities programmed in advance, but automatically learns the correct, common patterns and recognizes the deviations; is able to detect both common and rare faults, is particularly suitable for detecting unique, unexpected errors that are difficult or impossible to prepare in advance; universally capable to replace several different conventional systems in production fault detection, making quality assurance cost-effective; with the help of a one-time investment, the defective products appearing on the production line can be filtered off with unprecedented efficiency and the number of scraps can significantly be reduced can be used at any point in production, can easily be moved, does not require a fixed design or conversion around the production lines; integration into the production system is possible but not necessary, works independently; does not require lengthy training, significant and continuous operator involvement and external physical support: extra lighting, control, shading; can be tried immediately, there is no need to develop for special purpose, just to set it up.